Oil Tanker Truck Trailer Tanker Body Parts

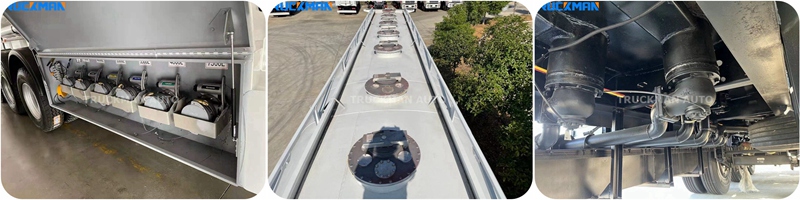

Oil tanker truck trailer tank body including the subsea valve, breathing valve, manhole, discharge valve, anti-overflow probe, oil and gas recovery valve, side plate vent valve, these is essential spare parts for tanker body. With 1-9 pcs compartment is optional, loading capacity from 30000 liter to 55000 liter, the axle have 2-4 axle available, BPW, ZY and FUWA brand optional.

Oil Tanker Truck Trailer Specification

Description | Parameter Value |

Product Name | Oil Tanker Truck Trailer |

Application | Oil and fuel transport |

Suspension | Heavy duty mechanical model |

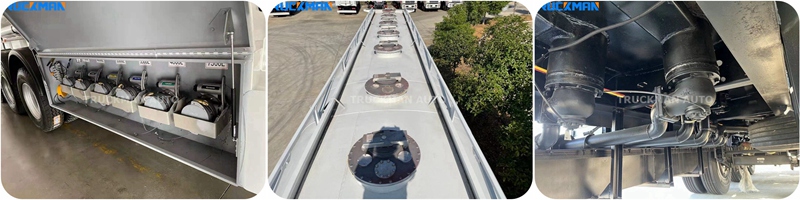

Axle | 3 axle, 3x16 tons, ZY, FUWA, BPW |

Tire | 315/80R22.5, 12.00R20, 12 pcs, LINGLONG |

Leaf Spring | 90x16mmx10pcsx6sets, 60# steel |

Tractor Pin | 90#, 3.5 inch |

Tanker Body | 45000 liter |

Support Leg | 28 tons, FUWA or JOST |

Dimension | 12500x2580x3750mm |

The oil tanker truck trailer specification only for your reference, we can manufacture other oil tanker truck trailer basic your request.

Oil Tanker Truck Trailer Detail

The oil tanker truck trailer manhole adopt the Europe standard, the size of hole is 500mm. It’s can easier to into tanker body clearance and maintenance the body. End plate thickness is 6mm and tanker body is 5mm, every compartment with wave plate, reduce the impact of fuel on the tank to meet the standard oil etc haulage.

Oil Tanker Truck Trailer Main Beam Maintenance Method

1. In order to ensure the cleanliness of the tanker body, the oil tank and the oil delivery system should be cleaned regularly. The inner and outer joints of the oil delivery hose should be regularly smeared with lubricating oil. After each operation of the oil pipe, it should be cleaned in time to ensure that the inside of the pipe is clean.

2. The use and maintenance of the oil pump shall be carried out in strict accordance with its operation and maintenance instructions.

3. Before the refueling operation, you must use a pole to insert it into the wet soil. The grounding tape of the oil truck should be grounded. During the operation, you should always maintain good static electricity.

4. Safety valve and filter net should be checked and cleaned frequently.

5. Tanker body and piping systems should be cleaned regularly. Regularly check whether the joints of the pipeline system are well connected and the sealing is reliable.